Updated: November 18, 2014

Quick-Links (click to navigate directly to the indexed topic):

Bottling

Given

the quantity of unsubstantiated misinformation that has been published

(and subsequently plagiarized and republished ad nauseum) for many

years, documentation of facts detailing the

During one of his visits to Doc Pemberton’s ramshackle

headquarters, Dobbs (Samuel Candler Dobbs, Asa Candler’s nephew) spotted

the primitive bottling operation under the coal shed out in the

backyard, and he was fascinated.

The Matthews machine was little more than a wooden table with

tubes connected to a generator and a pair of crude metal cylinders.

It had hand and foot levers that were used to lower a valve,

squirt syrup and carbonated water into a bottle, and secure an internal

rubber disk and wire contraption known as a Hutchinson stopper as a

seal. The carbonation was

provided by the old-fashioned, malodorous method of mixing sulfuric acid

and marble dust, and then forcing the escaping gas into water held under

pressure in one of the cylinders.

The process was ‘typically unsanitary, dirty, and antique,’ Dobbs

had to admit…Bottles with

Thomas (Benjamin Franklin Thomas) scraped together

several hundred dollars and opened a bottling plant in

Customers faced a different sort of danger: spoilage.

The

Good grief!

The author’s reprinting of the tired old myth attributing the term

“soda pop” to

Given the volume of material and illustrations included in this portion of the site, the topical outline that follows is designed to function as a road map that will hopefully allow users to find and access desired information more quickly. Clicking on an underlined heading opens a separate window displaying additional information about that specific topic. Close the window to return to the previous page you were reading.

The American Bottling System

Today’s consumers give little

thought to soft drink bottling; product pricing and packaging

convenience are their primary considerations.

Most of us probably envision computer-controlled processing lines

of fast moving bottles (and cans) being filled by automated dispensing

machinery, followed quickly by automated sealing and packaging.

Obviously, soft drink bottling has evolved greatly during the

past two centuries. Soda bottling

processes utilized during the 1879 – World War

I "Hutchinson era" have remained a mystery for too long.

Many people are content simply knowing

Pre-Hutchinson Era Soft Drink Bottling

During the earliest days of the soda and mineral water industry, consumers traveled to the source of the products, rather than the products being packaged for delivery to them. This included people going to spas located at or near mineral water springs, and also purchasing drinks dispensed from soda fountains that were typically operated in conjunction with drug stores. The concept of packaging soda and mineral water in glass and stoneware bottles for delivery to customers didn’t develop as an industry and catch on with consumers until the 1830s-1840s.

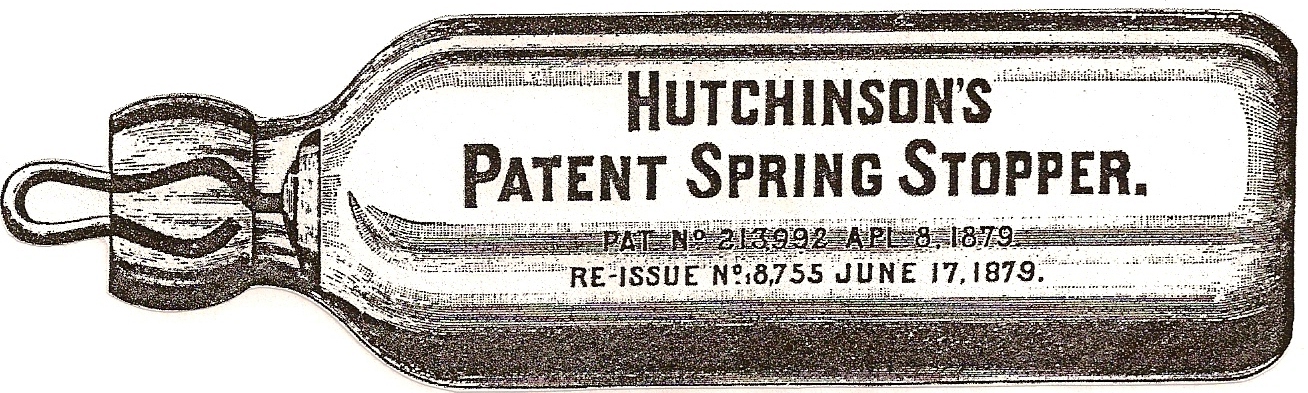

Hutchinson's Patent Spring Stoppers

W. H. Hutchinson and Son advertised their Hutchinson's Patent Spring Stoppers as "perfect," and "sure to become the only Stopper used for Soda and Mineral Water Bottles." Although their stoppers weren't perfect, they were by far the closure of choice for a majority of North American soda bottlers and their customers during the Hutchinson era. The enormous success enjoyed by W. H. Hutchinson and Son was the end result of a closure methodology accepted by bottlers and customers, plus a consistent and prolific advertising program. The following pages include information about how Hutchinson's Patent Spring Stoppers were marketed, descriptions of stopper-related tools, and day-to-day hints provided by bottlers who used Hutchinson stoppers.

Hutchinson Bottles

Several tidbits of information

incorporated into W. H. Hutchinson and Son’s advertising materials

provide clues concerning design of the bottles that utilized

The Hutchinson Bottling Process

The extensive information presented here was gleaned from very-difficult-to-obtain, original source materials. Each sequential step in the Hutchinson bottling process is described in considerable detail, with illustrations provided wherever possible. We believe this is the most accurate and detailed explanation of the Hutchinson bottling process that has ever been documented.

HutchBook.com

HutchBook.com