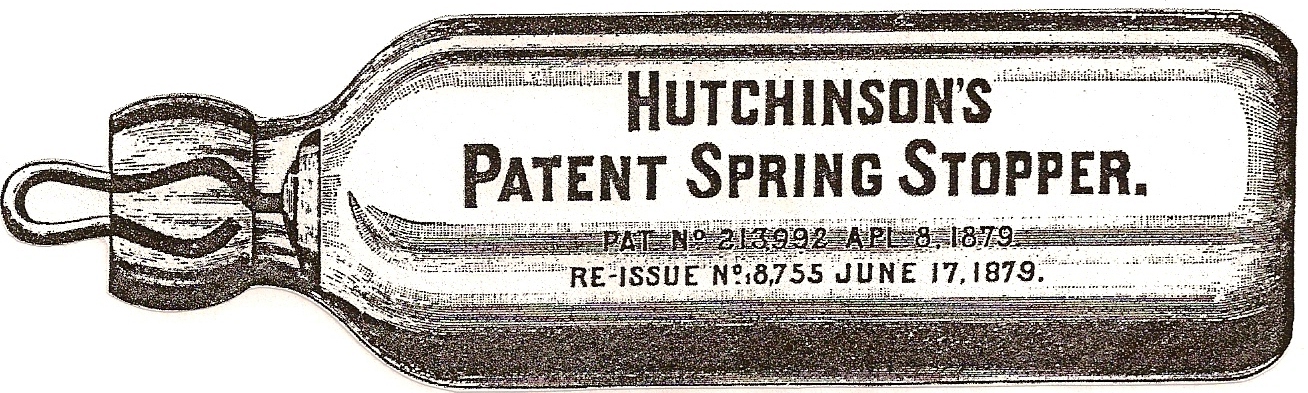

Hutchinson Stopper Repair

The 1889 W. H. Hutchinson &

Son catalog included this list of product “advantages” that provide

clues to typical Hutchinson Patent Spring Stopper maintenance

activities:

First.

The Hutchinson Stopper is connected with a spring handle by a single

wire, which makes the liability for collecting dirt very slight compared

with those Stoppers having a jointed or hinged bail, or having two wires

connected with the stopper or valve, which are very hard to clean when

they get dirty.

Second. The Spring in the Hutchinson

Stopper is unlimited in its movement, consequently adjusts itself to all

sizes of throats, and any little variation in the size of the throat of

the bottle makes no difference in its working well.

All other Stoppers imitating ours, that is, having a spring

action to hold them open and closed, have a limited movement of the

spring and are liable, through a slight wear of the wire or variation in

the size of the neck of the bottle, to become loose, and are therefore

useless as a perfect stopper.

Third. The Hutchinson Stopper is made very

strong; the spring being of heavy tinned brass wire, which is not liable

to break or get out of place from hard usage.

Unlike the other stoppers made, which, in order to save time and

money, are too light to stand hard usage, or the hinged or jointed

stopper, which is easily broken or becomes unjointed inside of the

bottle making them useless, and almost impossible to extract them from

the bottle.

Fourth. The Hutchinson Stopper can be

easily extracted from the bottles, and if the rubber washer gets out of

order a new one can be put on, and the Stopper will be good as ever.

The rubber washer is the only part of the Stopper which ever wears out,

and it can be easily replaced with new when desired, which is another

distinguishing feature of

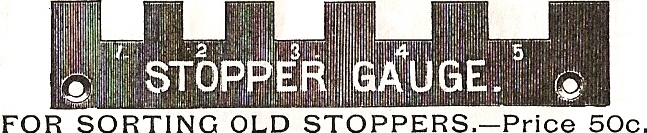

Stopper gauges were used to sort stoppers by their

five different button widths.

The 1908 W. H. Hutchinson and Son

Bottler’s Book

advertising copy specified “This gauge shows exactly the various sized

stoppers we make and will be very useful in sorting old stoppers.”

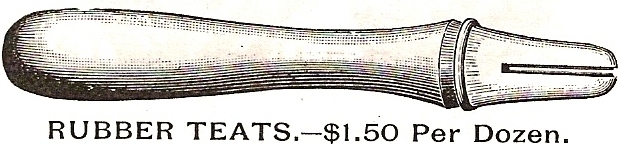

The 1889

W. H. Hutchinson & Son

Bottlers Supplies catalog advertised a rubber teat that was:

…put up on a split handle, adapted to straddle the

stopper spring in the bottle, when the rubber comes in contact with the

throat of the bottle, and by turning it around removes all the dirt.

It is not necessary to use this all the time, but if necessary,

it can be done very quickly.

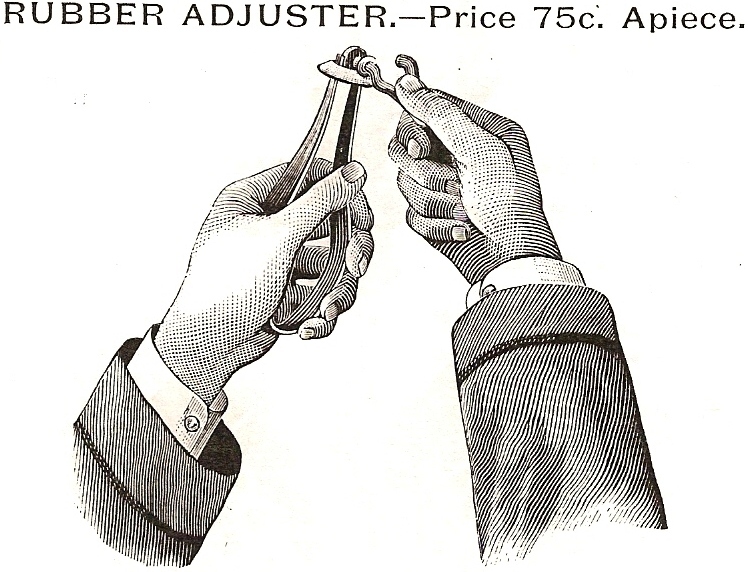

The 1889 W. H. Hutchinson and

Son Bottlers Supplies

catalog also offered rubber adjusters that were utilized to attach

replacement rubber washers onto stoppers:

The W. H. Hutchinson and Son

1908 Bottler’s Book

included the same illustration, but the price had been dropped to $ .50

and a footnote mentioned “A better way is to slip the rubber on the wire

of the stopper and then pull it over the small edge of the button with a

pair of pliers.” The same

catalog also offered:

The Superior Rubber Adjuster

Save time and labor, which means money, by re-rubbering old Soda Stoppers.

The following

USE BURNT

SUGAR.

By J. C. O’Bannon,

Bottlers who have complaints of the bad odor of

their Soda will find that many times it is the cause of the rubber

discs in the

TO MAKE RUBBER STOPPERS TASTELESS.

By J. E. Daigre & Son,

Cover the stoppers with water, add a few ounces of

lump sugar and let them soak for a few days, stirring once or twice

daily with a stick.

After this treatment wash them and they are ready for use.

TO SAVE RUBBER DISCS.

By E. Goltz & Son,

When rubber disc on spring stoppers get hard, soak

half an hour in two parts Ammonia and one part water.

SPRING STOPPERS.

By Commerce Bottling & Mfg.

Co., Commerce,

We find that when putting new rubbers on spring

stoppers if the bottom of the stopper is scraped with a knife it

will do away with a sediment in the goods, that very often you

cannot tell the cause of.

Shotting will not take this off, but you can scrape it off

without injury to the stopper.

USE OF SPRING STOPPERS.

By Louis G. Uehling, Hooper

Bottling Works, Hooper,

Save all our spring stoppers out of broken

bottles, and those you pull out of bottles when rubbers are worn out

and put on new rubber discs and you will find there is quite a

little account saved each year.

Any supply house will supply you with all the rubber discs

you need at 35 cents to 50 cents per gross.

Your stoppers thus repaired will be as good as new.

TO CLEAN

By C. N. Mead,

Take a 5 gallon keg, cut a hole in the head or

side, put in some fine sand and a little washing powder or Gold

Dust, take the old rubbers off, then put the stoppers in the keg and

give them a good rolling for a few minutes.

You will find the stoppers bright and good as new.

Then put new rubbers on.

By John W. Radley,

In replacing rubber disc on

BALL STOPPERS.

By H. A. Ralu,

I have used in my Soda Water factory, four classes

of bottles, viz.: the ordinary cork bottles,

HutchBook.com

HutchBook.com