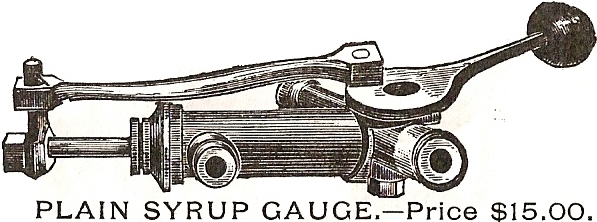

Syrup Gauges

Once the valves controlling the carbonated water and syrup lines were

opened, a

The

W. H. Hutchinson and Son

1908 Bottler’s Book listed the following “

When

the arm on the syrup gauge was pulled forward, a valve automatically

opened causing a rush of carbonated water to wash the syrup and

carbonated water thru the filling head and into the bottle.

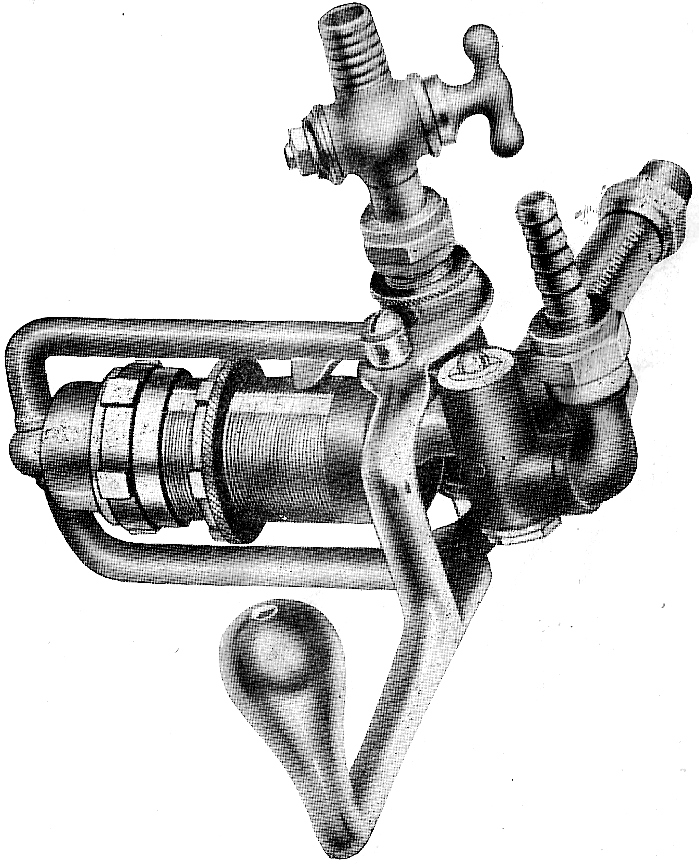

If the table didn’t have an optional automatic snifting valve,

the head assembly had to be raised two or three times in order for the

trapped air to escape, allowing more soda to flow until the bottle was

properly filled. Snifting

was a highly important step in the bottling process.

The 1910 W. H.

Hutchinson and Son Bottlers’ Supplies catalog emphasized:

Probably the most important item in the process is the

snifting. In this operation

the atmospheric air in the bottles is driven out and replaced by the

carbonic acid gas. If done

too hastily there is danger of loss of gas and the product resulting

will not be under high enough pressure.

If not snifted sufficiently, air will remain in the bottles,

depreciating the sparkling appearance so much desired and rendering

fermentation possible, and in fact probable.

Another carbonic acid gas saving invention perfected

during the latter years of the

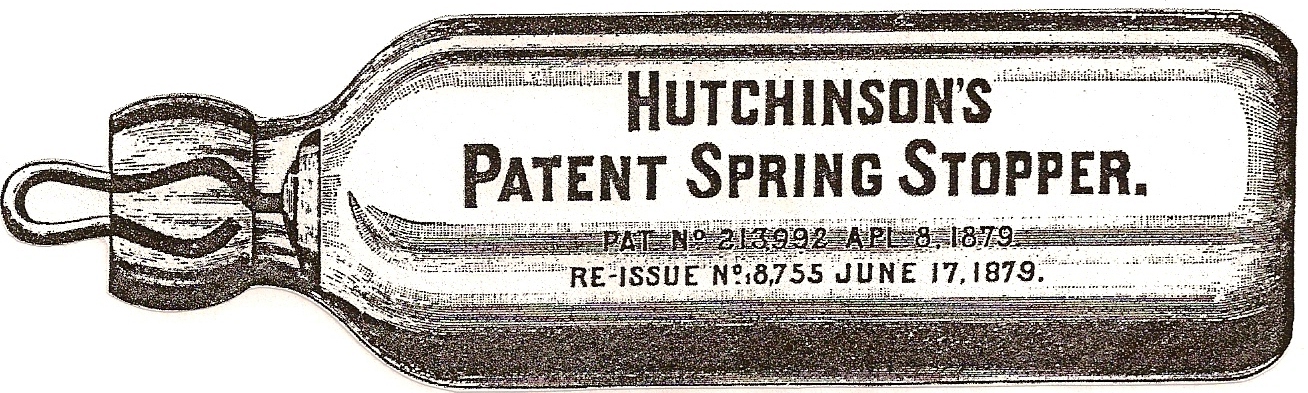

The foot snifting process was another standard

bottling procedure impacted by introduction of the crown cork system.

The 1917 W. H.

Hutchinson & Son Catalog and Price List cautioned:

When using the old Hutchinson Stopper, now out of

date, it was the custom to snift with the foot, a practice which enabled

the bottler to fill

HutchBook.com

HutchBook.com