Henry W. Putnam Stopper Fastening

U. S. Patent Number: 1,606 (Reissue) Patented: January 19, 1864

Henry W.

Putnam’s patent application specified:

I, Henry W. Putnam, of…

Fastenings for bottles have heretofore been made in

which a strap of metal has extended over the cork from a hinge or joint

formed on each side of the neck of the bottle by a second metallic

strip. This device is costly

to manufacture, and is liable to be displaced in use by the pressure

upon the cork, because such metal strap has had a notch formed therein

for the plunger, (that holds in said cork after the bottle has been

filled,) which notch allows the cork to project at this point, and by

springing up the metal on the sides of the notch form an inclined plane,

against which the pressure acts to force the fastener aside and relieve

the cork.

The nature of my said invention consists in forming

the fastener of wire bent in such a manner that if the pressure upon the

cork is sufficient to bend said wire fastener it will retain the cork

more firmly and the cork require to be pushed in before the fastener can

be pushed aside, thus causing the pressure to render the fastening more

secure instead of more liable to failure.

I also form joints for securing the fastener and forming a hinge

upon which it may be turned aside by bending the ends of such wires at

right angles, or nearly so, to the sides of the fastener, and I make use

of a wire for attaching this fastener to the bottle, in which the eyes

are formed for receiving the ends of the fastener, and on which the said

fastener swings, thus producing by one piece of wire a much more simple,

effective, and cheap attachment than any before made.

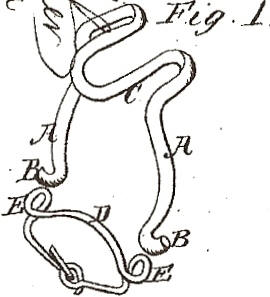

In the accompanying drawings, Figure 1 represents the

fastener with the two parts separated from each other.

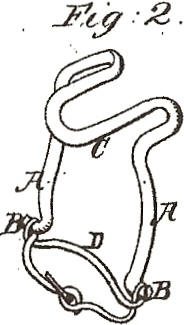

Fig. 2 represents the fastener with the two parts united.

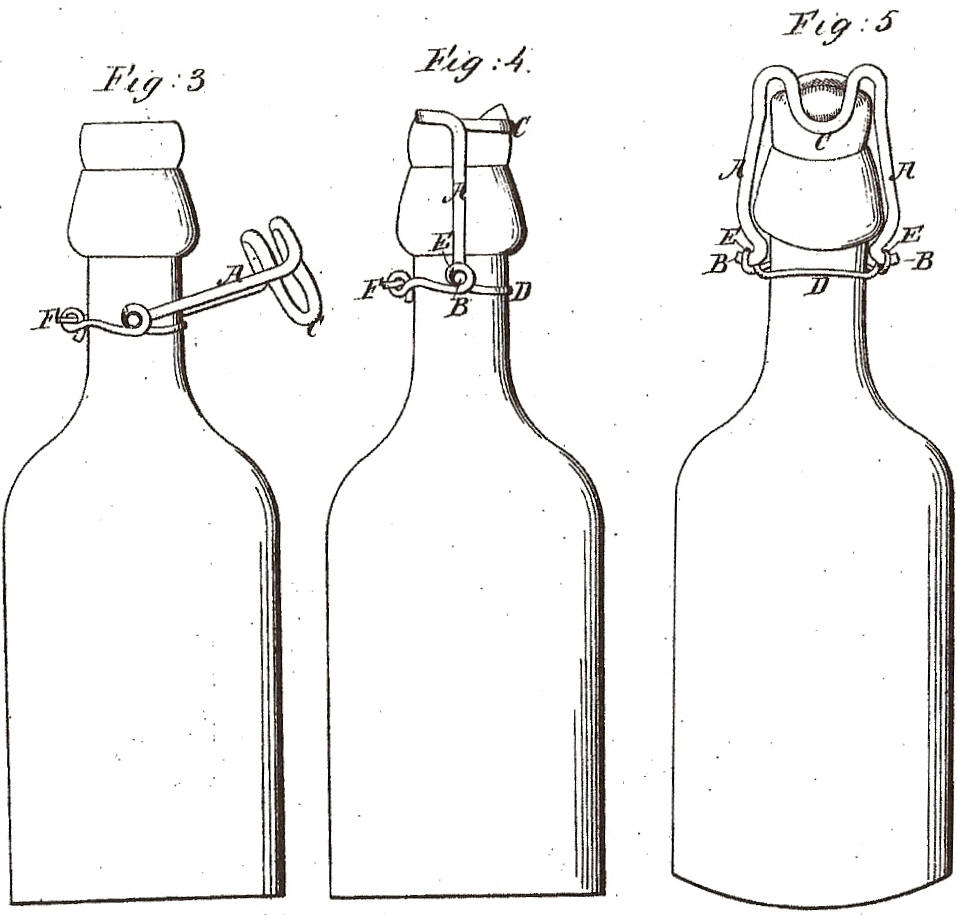

Fig. 3 represents the fastener with one part loosely inclosing

the neck of the bottle, and Figs. 4 and 5 show different views of the

fastener in use…

The bottles are filled under a pressure of two or

three atmospheres for the purpose of holding the carbonic-acid gas in

solution with which the liquid is charged…

The manner of using this fastening is as follows: The

bottle is placed under the fountain and its neck encircled at the top by

the tube that conveys the saturated water or other liquid into the

bottle. The cork being

placed in the tube above the side pipe that admits the fluid into the

bottle, by turning a stop-cock the bottle becomes filled with the

liquid, and by means of the piston above the cork the cork is forced

into the neck of the bottle, the fastening being turned aside, as seen

in Fig. 3. When the bottle

is full and the cork inserted, the pipe is elevated, the piston still

holding the cork. The

fastener is then forced over the end of the cork, as seen in Figs. 4 and

5, in which position it is held from being pressed out by the expansion

of the gas…It is sometimes necessary to force in the cork before the

fastener can be released, which is effected by pressing with the thumb

on the sides A of the wire fastening and turning it off into the position of Fig.

3.

Comments:

This summary includes the illustrations accompanying

the original 1859 patent filing, plus selected portions of the 1864

patent reissue specifications.

Putnam’s fastener clearly illustrates one of the most popular

methods used to hold externally inserted corks into blob top soda

bottles. Looping a wire over

the cork and twisting it around the neck beneath the blob top was also

quite common. Blob top soda

bottles are sometimes incorrectly identified as

HutchBook.com

HutchBook.com