William Painter Bottle Stopper

William

Painter filed separate “Bottle Sealing Device” patent applications

November 5, 1889 (renewed October 6, 1891), June 16, 1890, and May 19,

1891. All three patents were

granted February 2, 1892.

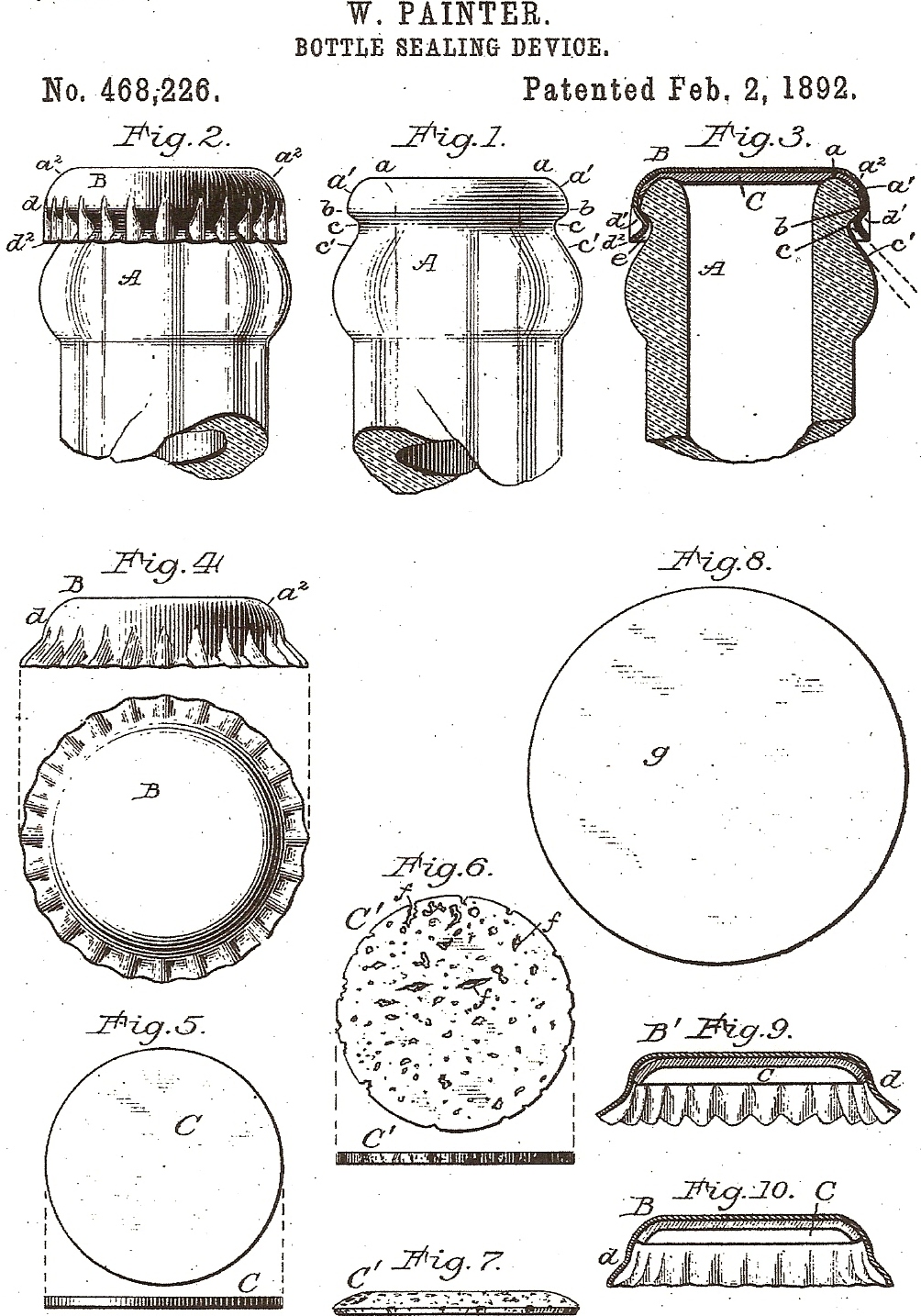

Painter’s highly-detailed drawings and patent specifications clearly

illustrate and explain the evolutionary development of his “Crown Cork”

system. The illustrations

shown above accompanied Patent No. 468,226 (the 1891 filing) and

specified:

I, William Painter, of Baltimore…Maryland, have

invented certain new and useful Improvements in Bottle-Sealing

Devices…(pertaining to) the sealing of bottles by the use of

compressible packing-disks and metallic caps, which have flanges bent

into reliable locking engagement with annular locking-shoulders on the

heads of bottles, while the packing-disk is in each case under heavy

compression and in enveloping contact with the lip of the bottle.

In order that the status of my present improvements

may be properly defined with respect of novelty and utility, I deem it

proper to briefly review the prior art in this special connection.

So far as my knowledge extends, I am the first to seal bottles by

means of sealing-disks each compressed into close solid contact with the

lip of the bottle and maintained in that condition by means of a flanged

metallic sealing-cap, the flange of which is bent or crimped into

locking contact (while the disk is under pressure) with an appropriate

annular locking-shoulder on the head of the bottle, as well as the first

to devise methods and means by which in the use of such caps and disks

liquids can be bottled under even the highest gaseous pressures employed

in this art…

Considerable manual force must be applied for

detaching the caps from the bottles, and therefore in the early stages

of my invention the use of loops of some kind or of equivalent holes in

the tops of the caps was deemed essential, and the caps had wide or deep

pendent flanges and they contained sealing-disks of considerable bulk or

thickness…Contingencies led, after much devising and experimenting, to

the production of a cap without a loop or hole in its top, a thinner

disk, and consequently narrower flanges, thus substantially reducing the

cost of the sealing device as a whole without decreasing, but in fact

increasing, the efficiency of the applied cap, and also securing higher

sealing efficiency by the use of a less expensive disk…

These improved caps having in themselves no special

provision – such as loops or openings in their tops – for detaching them

from bottles led to my further devising a novel method of their

combination with the bottle, in accordance with which the pendent edge

of the flange below the bent portion is so far projected from the

adjacent surface of the bottle-head as to afford an engaging-shoulder,

to which a bottle-opener could be readily applied…The disadvantages to

consumers incident to a positive requirement for the use of

specially-constructed openers are obvious, and to avoid them I have now

so devised my loopless and close-topped caps and have so organized a

combination thereof with the bottles that the cans can be almost as

readily detached by the use of a knife, a screw-driver, a nail, an

ice-pick, or any usually and readily available pointed instrument…

Referring to the drawings, Figure 1, in side view,

illustrates a bottle-head adapted for use in combination with my cap and

a sealing-disk. Figs. 2 and

3 respectively illustrate in side view and section a bottle-head with

one of my caps and a sealing-disk applied thereto.

Fig. 4, in side and top views, illustrates a cap prior to its

application to a bottle.

Fig. 5, in top and edge views, illustrates a sealing-disk of a composite

character in its normal form.

Fig. 6, in top and edge views, illustrates a sealing-disk in its

normal condition composed of ordinary cork and fairly indicating the

open or porous character of such disks as have been successfully used by

me with my caps in maintaining gas or air tight closure even under much

higher pressures than are ever needed in bottling.

Fig. 7 illustrates a cork disk in the form which is made to

assume within the cap and after it has been subjected to heavy pressure

for reducing its hard spots.

Figs. 8, 9, and 10 respectively illustrate a sheet-metal blank from

which the cap is formed, the shape first developed therefrom and the

final shape, these being in section with the sealing-disks therein.

Comments:

William Painter’s patent specifications provide

detailed insight into the numerous challenges he encountered and

successfully overcame while designing caps, seals, the bottle head’s

contoured lip, etc. The

complete patent specifications are fascinating, but aren’t the focus of

this review and therefore were not included in their entirety.

Painter's highly successful Crown Cork seal capped off (pun

intended) the broad range of bottle stopper patents that triggered the

curtain to fall on the

HutchBook.com

HutchBook.com