Charles C. Haley Bottle Stopper

Charles

C. Haley’s patent application (assigned to Henry A. Haussling and Adell

A. Haley) was filed December 10, 1888 and specified:

I, Charles A. Haley…of…Newark…New Jersey, have

invented certain new and useful Improvements in Bottle-Stoppers; and I

do hereby declare the following to be a full, clear, and exact

description of the invention, such as will enable others skilled in the

art to which it appertains to make and use the same…

The object of this invention is to enable bottles

supplied with permanently-attached stoppers of a certain class to be

washed with greater facility by means of the ordinary washing-machines

now in common use; to allow of and to obtain a more perfect cleansing of

both the bottle and stopper; to allow of the substitution or replacing

of defective parts without much labor or cost; to reduce the danger of

opening the bottle when the projecting bail is accidentally struck…

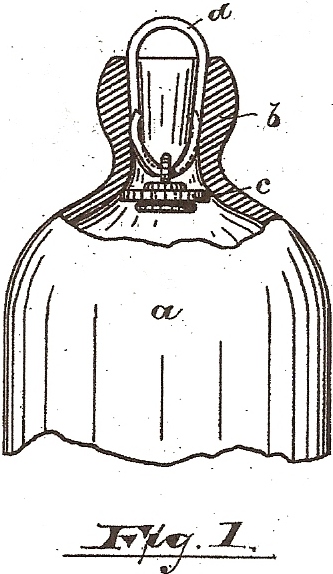

Figure 1 is a side elevation of the improved stopper

in connection with the bottle, the upper part of said bottle being shown

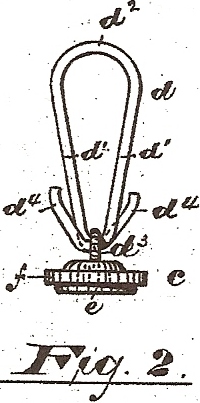

in section. Fig. 2 is a

similar elevation of the stopper disconnected from the bottle; and Fig.

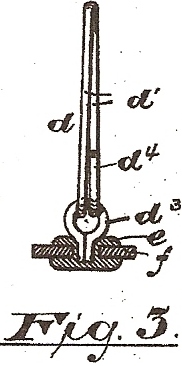

3 is a side elevation of said stopper, the “button” being shown in

section…

Heretofore in devices more closely resembling my

improvement the said bail, consisting of bent wire, has been rigidly

secured to the button by means of solder at one end and provided with a

free end, which served only to engage the inner side of the neck or

mouth of the bottle to hold the said button in place, the said bail

serving to hold the button away from its bearings on the inside of the

bottle in the process of emptying and filling the said bottle.

In the improved device the bail and button have a

jointed relation to one another, whereby when the stopper is pressed

back or into the bottle the said button may turn in its relation to the

bail, so as to allow the cleansing brushes or tools of the washing and

rinsing or swabbing machines to pass down into the body of the bottle,

the bristles or washing-surfaces of the tools passing over the upper

surface of the button, so as to perfectly cleanse the same, as they

could not were the buttons held rigidly at right angles to the bail.

One method of joining the parts is shown clearly in

Fig. 3, in which d3 indicates

an eye formed on or secured to the metal portion of body

e of the button, the method

shown being to form an eye or eyelet-wire, as indicated, and cast the

body metal around the ends thereof to hold them together.

The body metal is formed to resemble a disk, having a

recess, in which is secured a rubber or other suitable washer,

f, adapted to engage the

inside of the bottle and form an impervious joint therewith in the usual

manner.

The bail d

is bent, as indicated more clearly in Fig. 2, the same providing two

hooked arms, d’ d’, connected, as at d2,

to form a finger-loop, by means of which the bail may be grasped by the

finger or by the ordinary hook commonly found on the bottling-bench, to

draw the said bail and its connections upward…The opposite ends of the

hooked arms lie laterally adjacent to one another and extend oppositely

through the eyelet d3, so that

the said button is prevented from becoming detached from said bail.

The opposite ends, d4,

project beyond the parts d’ of

the bail, as shown in Fig. 2, forming spring-bearings which engage the

sides of the neck and hold the said bail in place.

By having the spring-arms formed as shown I secure to

free ends, which with an evenly-distributed power reduce the lateral

pressure on the neck and allow a more easy and even drawing of the parts

into place.

The body of the button may be of metal, of hard

rubber, or of any other suitable material.

Comments:

Several

Haley’s stopper was marketed as the “H. & H. H. Double

Spring Action Bottle Stopper” by the E. Berghausen Chemical Company in

Haley’s stoppers were also utilized by the Badger

State Bottling Company of

HutchBook.com

HutchBook.com