Albert Albertson Bottle Stopper

Albert

Albertson’s patent application was filed circa October 6, 1864, assigned

to his attorney, J. N. McIntire, and ultimately re-assigned to The Firm

of John Matthews in

I, Albert Albertson, of

My present invention relates more particularly to a

bottle and stopper intended for bottling “still” liquors, (but may be

used to advantage with all liquids), and has for its object to

accomplish the closing of the mouth of the bottle by a stopper contained

within the bottle, and so constructed that as the bottle is filled the

contained liquid will float the stopper into position for closing the

bottle, which may be rendered more complete by taking hold of the

protruding end of the stopper and pulling it outward…

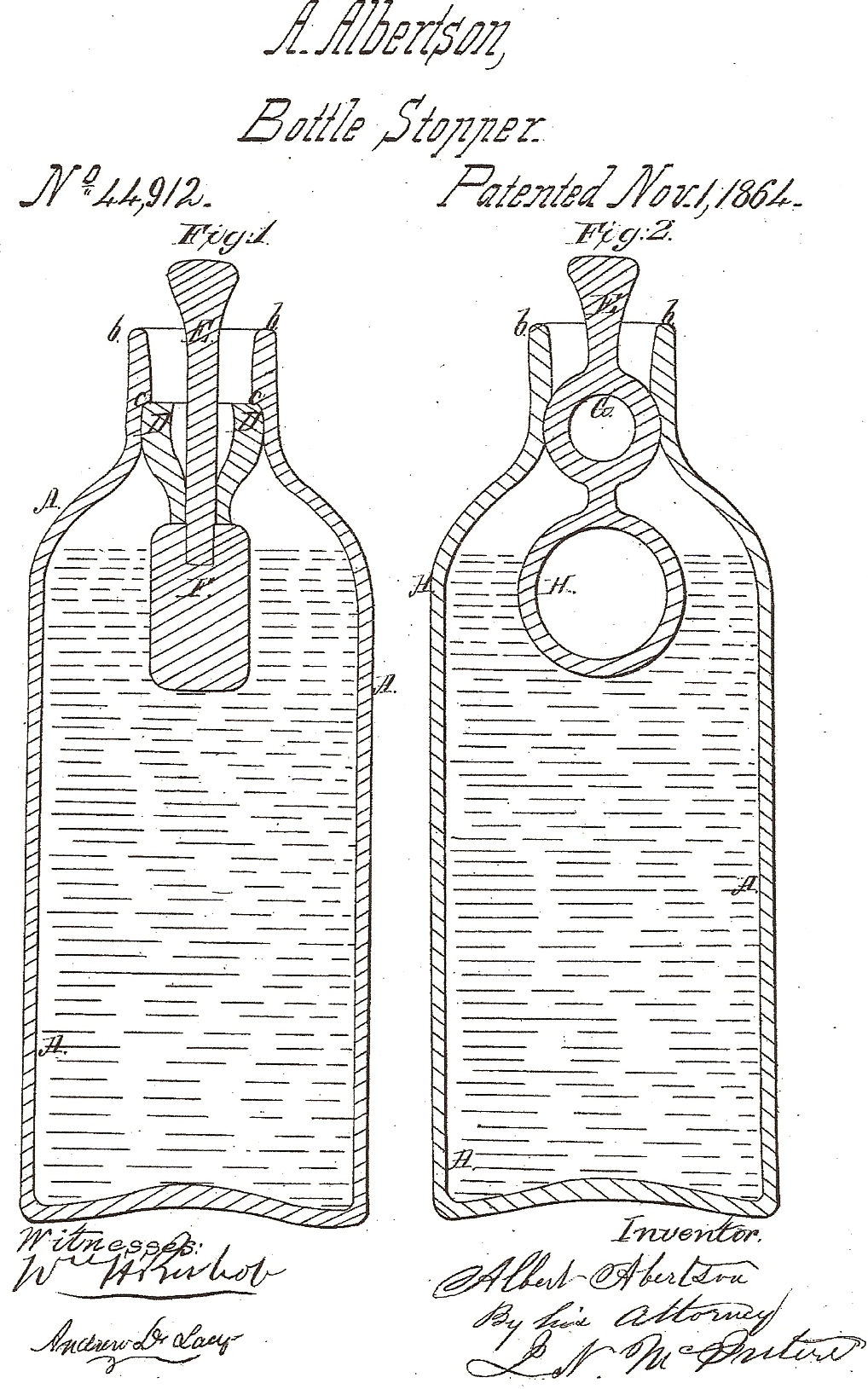

Figure 1 is a vertical section of a soda-water bottle

with my invention adapted thereto, and Fig. 2 is a similar view of

another bottle, and illustrating a modification of my improved stopping

device…

At Fig. 1…A

is the bottle, the neck b of

which should be formed with an annular shoulder on the interior, as seen

at c. The stopper is

composed of a float, E, of

cork or other material, (whose specific gravity is much less than that

of water,) from which extends a stem,

E, formed with a knob-like

upper end, and a valve or closing portion,

D, which I have shown as formed of rubber and surrounding the stem

E immediately above the cork

or float F,

the valve portion E is

made nearly conical in shape and hollow at its upper (larger) portion,

as clearly shown, so that it may be readily compressed or squeezed

through the mouth and neck of the bottle down past the shoulder

c, and so that by attempting

to pull it back through the neck of the bottle the upper edge of the

valve will be caused to impinge against the annular shoulder

c, and be by the latter

“upset” or bulged outward, and the valve be thereby wedged tightly into

the neck of the bottle and the latter be effectually closed.

The entire length of the stopping device

D E F, it will be seen, is greater than the diameter of the bottle,

so that after the stopper is supplied to the interior of the bottle it

cannot become deranged therein by being turned upside down…

If necessary, the adjustment of the stopper to its

seat may be assisted by the finger of the filler or operator moving the

upper end of stem E toward the

center of the mouth or neck of the bottle, whereby the mouth of the

bottle will be closed…the operator should…pull the stopper upward until

its valve is wedged sufficiently tight into the seat in the neck of the

bottle to insure a perfectly tight joint and air-tight stopping of the

bottle.

At Fig. 2 I have shown the stopper formed of two

spheres, G and H, and a stem,

E, the upper and smaller

globe, G, acting as a valve in

the neck of the bottle, and the lower and larger globe,

H, acting as a float.

In this modification I have illustrated the stopper as if formed

entirely of rubber, the stem portion being tolerably hard and stiff,

while the globes G and H are of soft rubber

and hollow…I have shown the interior of the neck of the bottle of a

slightly different shape, and so formed that the ball

G can be more readily squeezed through in one direction than in the

other, so that while the stopper may be easily forced down into the

bottle, it cannot be very readily forced out again…

To open and discharge the contents of a bottle closed

as described by my invention, it is only necessary to push the stem of

the stopper inward (by pressing on its protruding knob or end) to loosen

the valve from its seat in the neck of the bottle and then invert the

bottle, when the entire stopper will float toward the base of the bottle

and allow the contents to run freely out at the mouth.

Comments:

These improvements focused on turning the bottom of

the stopper into a float, speeding movement of the stopper into the

mouth of the bottle and causing it to seat more quickly.

The stopper illustrated in Figure 1 was made of rubber with the

lower, float portion made of cork.

The bottle needed to have an interior, annular shoulder against

which the stopper seated.

The stopper illustrated in Figure 2 was made entirely of rubber and the

bottle did not require an interior, annular shoulder.

These innovations clearly influenced the design for Matthews’

Patent No. 67,781 of August 13, 1867.

HutchBook.com

HutchBook.com