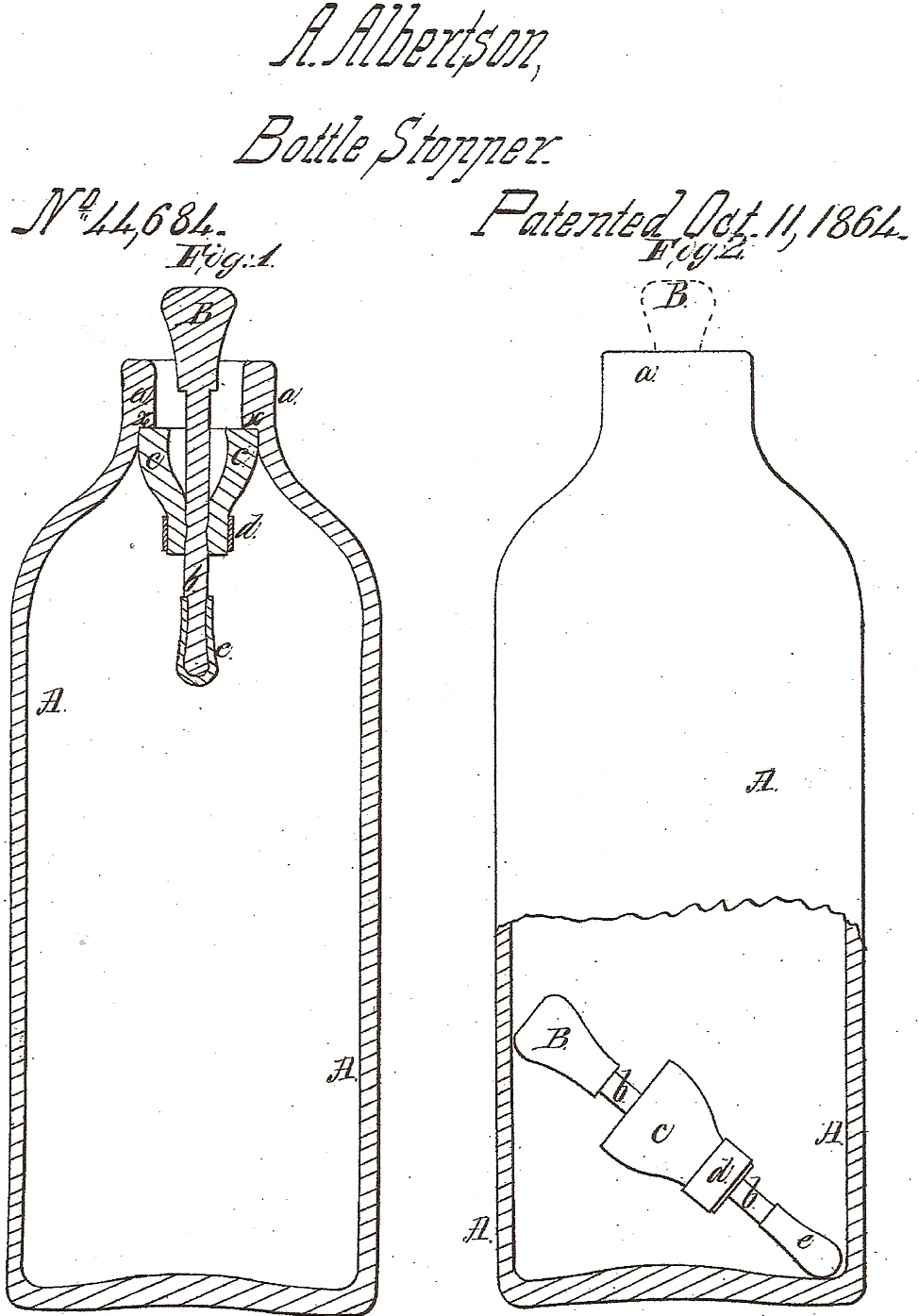

Albert Albertson Bottle Stopper

Albert Albertson’s patent

application was filed circa August 8, 1864, assigned to J. N. McIntire,

his attorney, and ultimately re-assigned to the Firm of John Matthews in

I, Albert Albertson, of

Previous to my invention several methods of stopping

bottles have been suggested and patented, all having for a main object

to dispense with the employment of ordinary corks (which have to be

renewed at each filling of the bottles and are expensive) and avoid the

labor involved in the use of them, especially in bottling gaseous

liquids, where the cork has to be tied or otherwise secured in the mouth

of the bottle.

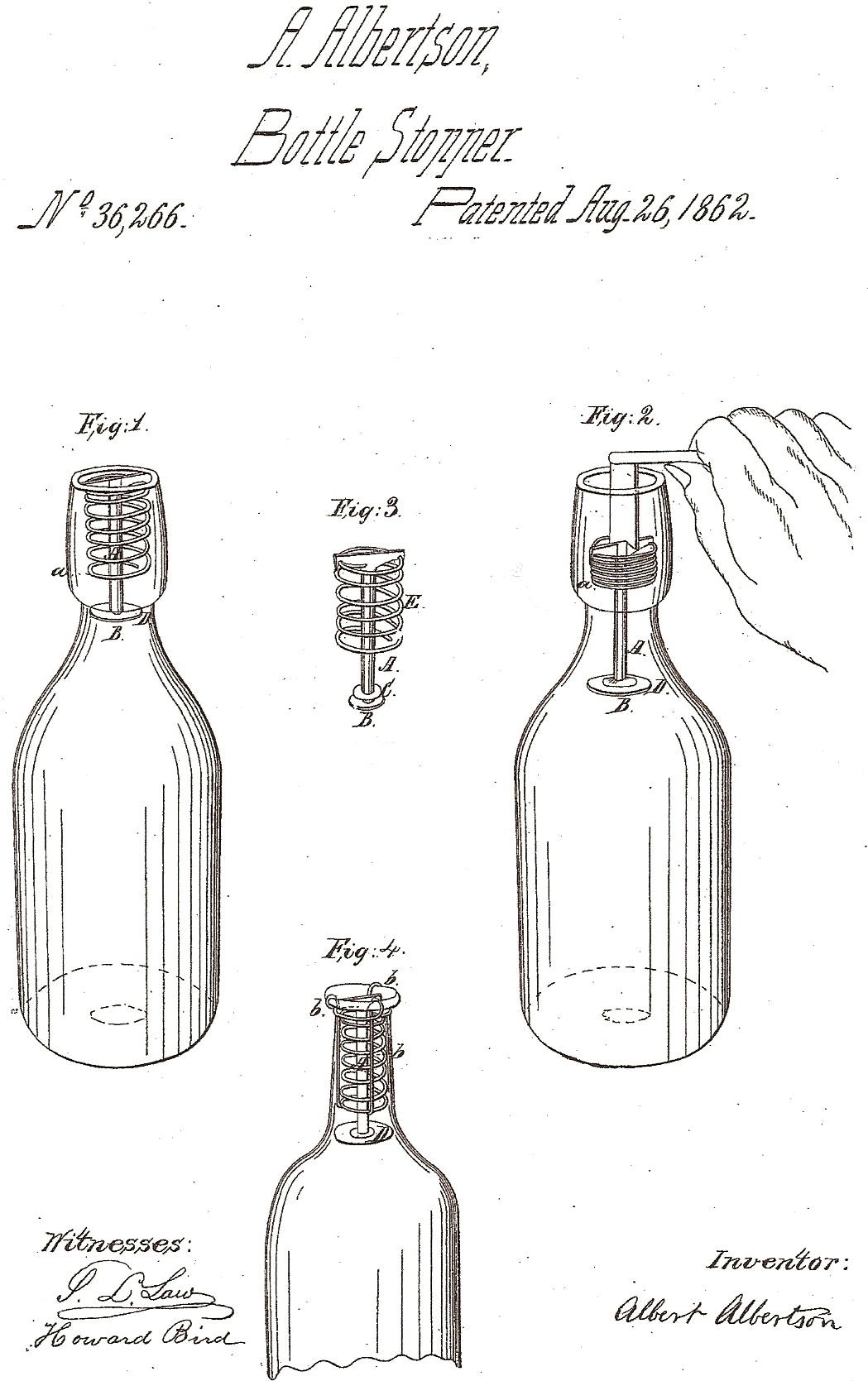

Among the inventions suggested heretofore, having for their objective the great desideratum of dispensing with the expensive and laborious system of corks and fastenings, the best method, to my knowledge, is that shown and described in Letters Patent granted to me on the 26th day of August, 1862 (see illustration);

but

experience and thorough practical tests have shown that in the method

patented to me there are serious objections when put into general use –

as, for instance, the liability of the mechanism to clog up, the

necessity of an instrument for the purpose of readily opening the mouth

of the bottle to empty it of its contents, and the liability of the

necks of the bottles, from their necessarily weak form, to break during

transportation or handling.

These objections and others I propose to effectually overcome by my

present invention, which has for a further object to produce a more

economical, durable, and desirable method of stopping bottles than any

heretofore known…

To those ends my invention consists in the employment

of a stopper which may be inserted through the neck of the bottle, and

so constructed that it can be brought into close contact with a suitable

bearing-surface or seat on the interior of the neck of the bottle to

close it, and be depressed or pushed down into the bottle to open

it…(and) any tendency to force it out will only tighten the joint

between the stopper and its seat in the bottle-neck…

My invention further consists in making the entire

stopper of a length exceeding the diameter of the bottle in which it is

to be used, so that the stopper while resting in the body of the bottle

cannot turn round, but must always present itself right end foremost to

the mouth of the bottle…

Figure 1 is a vertical or longitudinal section of a

bottle with the stopper represented in the position in which it closes

or stops the mouth of the bottle.

Fig. 2 is an elevation of the same, (with the lower portion of

the bottle broken out,) showing the position of the stopper after

opening or unstopping the bottle to empty it…

A is the bottle,

(of any shape or design,) on the interior of the neck of which I propose

to form a shoulder, as seen at x.

The stopper is formed of a stem or rod,

b, having a suitable knob

portion, B, and having secured

(or formed) on it a gutta-percha or other elastic or yielding valve or

cork, c. I have represented

the stem b as made of metal,

and with a thimble or cover, e,

of soft material – such as gutta-percha – at its lower end, the object

of which is to avoid any possibility of injuring the bottle by the

sudden contact with the glass of the hard stem, when the latter is

forced or drops down into the bottle in “opening.”

The valve portion

c, I have shown secured to the

stem b by means of a band or

collar, d, and an annular

depression in the stem b, into

which the yielding stock of c

is forced and held by the encircling-collar

d; but in lieu of this mode of

construction the entire stopper may be formed (if found practicable and

expedient) of rubber, the stem portion “hard,” with its lower end

“soft,” and the conical valve portion

c of the proper flexibility.

The position of the valve portion

c on the stem

b is such as to allow the knob

or upper end of the stopper to protrude a short distance beyond the

mouth of the bottle when the valve

c is…closed in order that the stopper may be readily forced down

into the bottle by pressure, or a blow with the hand to open the bottle…

I prefer to make the valve

c, as shown, conical, with

upper end hollow, and provide the interior of the neck with a shoulder,

x, for in this form of valve

and seat the stopper is readily forced up against its seat or shoulder

the valve c will be bulged or

upset and cannot be forced out, which is a desideratum where the

contents of the bottle embrace gas or fixed air – as, for instance, when

soda-water is contained…

To bottle soda-water and other gaseous liquids, (under

pressure), I take the bottle (thus provided with its stopper) and place

it in the filling-machine, in which the given quantity of water and gas

is supplied to the bottle, (the stopper remaining as seen in Fig. 2.)

I then invert the bottle while it is yet attached to the

supply-tube…when the stopper falls into the neck of the bottle, the

valve c resting in its seat, and in this position I disconnect the bottle

from the filling-machine, when the pressure within the bottle retains

the valve c against its seat

and keeps the bottle effectually closed.

When it is desired to empty the bottle, a slight blow or pressure

on top of the knob B will

cause the stopper to descend to the bottom of the bottle, as seen at

Fig. 2, and the liquid is poured out.

The stopper being of a much greater specific gravity than the

liquid and being so long, will not impede the flow of the liquid from

the bottle if it is gradually poured out…the emptied bottles are

returned to the factories (or filling-depots) and refilled as many times

as the duration of the bottle and stopper will permit.

Comments:

Albert Albertson’s innovations were important

developments in the evolution of bottle stoppers.

Bottles utilizing his August 26, 1862 and October 11, 1864

patents were manufactured by The Firm of John Matthews in

HutchBook.com

HutchBook.com